The most challenging piece of the government’s plan is retrofitting 440 power generation units, with a combined capacity of 166.5 Gigawatts (GW), with flue gas desulphurization (FGD) systems by December 2022 for plants near populous regions and the capital New Delhi, while utilities in less polluting areas have up to 2025 to comply or retire units. These plants represent about 54% of India’s installed power generation capacity and are all fueled by coal, which ranks them among the highest polluting industries in India. Installing the FGD systems serves to greatly reduce their emissions to atmosphere, specifically sulfur oxides (SOx).

Pollutant abatement control – technologies & solutions

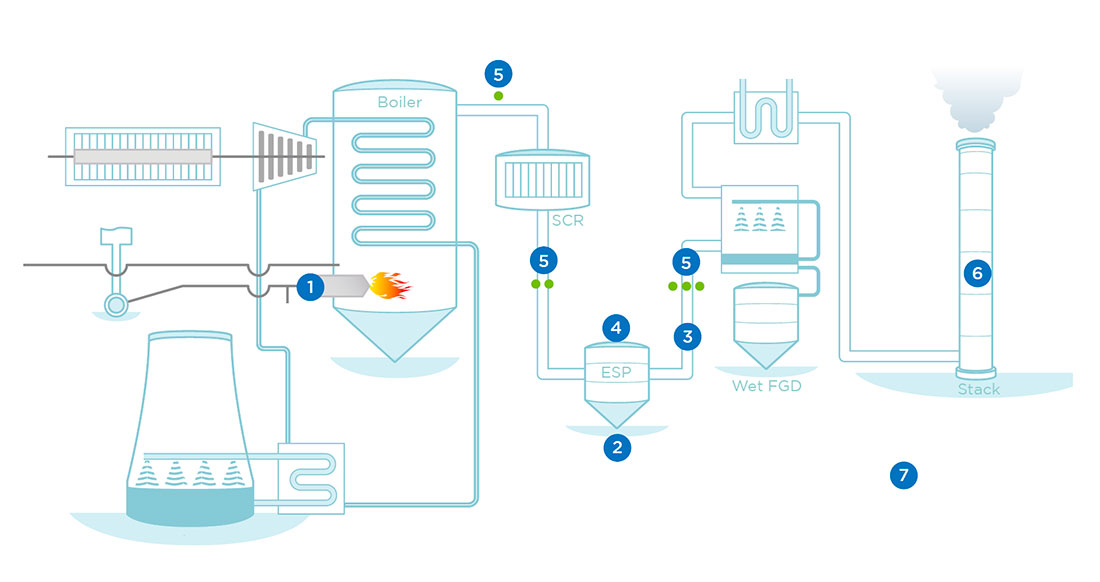

To calculate and precisely adjust this pollutant reduction, on-line monitoring of HCl, NOx or SO2 (precursor of SO3 and sulfuric acid derivates) must be set on the process upstream of the abatement plant. The advantage of flue gas Process monitoring with ENVEA’s MIR 9000 analyzer ensures that the pollutant abatement function is optimized, whilst reducing the overuse of valuable materials in the abatement process, in turn providing cost savings to the plant operator and minimizing pollutant releases. Measuring additionally the water content would additionally allow the detection of a possible leak in the boiler.

The dust (fly ash) is captured and removed from the flue gas by electrostatic precipitators (ESP), fabric bag filters or both. To ensure that the dust filtration plant is operating at its maximum efficiency and ensuring optimum pollutant control, we can consider ENVEA’s range of filter performance monitoring systems.

For bag filters, installation of our Electrodynamic sensors in the main flue gas outlet and the outlet of each filter compartment can confirm where leaking filter bags are present and give an overall picture of filter performance and life, greatly decreasing maintenance time and costs by highlighting the bag rows that need to be changed.

For plants with an ESP fitted, a mix of ENVEA’s ProScatter technology (light scatter) and real-time data collection provides precise data to the plant operators to enable adjustment of the voltages applied to the ESP plates, providing cost saving and emission optimization.

For wet FGDs ENVEA can use its ProScatter Extractive technology, enabling wet flue gas emissions monitoring that complies to standards.

To comply with NOx emission limits the application of ammonia or derivatives of ammonia (e. g. urea) as a reduction agent has proved successful. The nitrogen oxides in the flue-gas basically consist of NO and NO2 and are reduced to N2 and water vapor by the reduction agent. Two processes are important for the removal of nitrogen from flue-gases: selective non-catalytic reduction (SNCR) and selective catalytic reduction (SCR). In both these systems, the flow rate and control of NH3 must be continuously adjusted and controlled to prevent excess NH3 emissions (slip), to avoid ducts corrosion increase catalyst lifetime and reduce environmental impact and cost of reagents. To optimize this process, it is essential to use a gas analysis system for simultaneous and continuous monitoring of NH3 and/or NOx.

A recent report from the International Institute for Sustainable Development (IISD) says India aims for all plants having FGDs by 2022. The report also states, “The provision of data from continuous emission monitoring system (CEMS) devices installed in the emission stacks of plants, to the electricity regulator and the broader public must be a first priority.”

ENVEA’s involvement with the Power generation industry over many years accross the world, has led to the development of a unique range of process and pollution monitoring solutions, as well as approved (TÜV/UBA, MCERTS and Ex) technologies for in-stack measurement of gas, particulate, and flow rate. They allow to control in real time the efficiency of the FGD, DeNOx and ESP systems and to optimize the whole-plant’s efficiency through measurement & control, to reduce air pollution and facilitate legislative compliance. Furthermore, they help saving operational costs by reducing plant’s maintenance requirements and process downtime.

-

e-Series Sulfur dioxides Analyzer SO₂

AF22e

-

Ambient air dust monitoring

AirSafe 2

-

Indoor Monitor for Dust Exposure for PM1, PM2.5, PM4.25, PM10, TSP

AirSafe PM

-

Autonomous networks of sensor-based mini-stations

Cairnet®

-

e-Series carbon oxides Analyzer CO

CO12e

-

Total Hydrocarbons FID Analyzer

HC51M

-

Volatile Organic Compounds Analyzer BTEX

VOC72e

ENVEA’s solution for India’s power generation plants

- For NOx abatement control (DeNOx), the use of the NDIR heated and extractive multi-gas analyzer MIR 9000H, offering the capability of measuring the NH3+H2O or NH3+NOx+H2O simultaneously is recommended. The same analyzer can measure additionally other parameters such as CO, CO2 and O2 if required by the process. If sole the monitoring of NH3 is to be made, the use of the Cross Stack TDL sensor LAS 5000XD-NH3 offers fast response, in situ measurements.

- For bag filter dust removal efficiency control the use of our Electrodynamic sensors installed before and after the bag house.

- For the ESP dust removal efficiency control the use of the PCME Stack 602 DynamicOpacity monitor, installed before and after the ESP. We can also utilize an ENVEA Proscatter DM 170 backscatter sensor after the ESP for Process control, with the dual benefit of ensuring ESP control and ensuring that the bag filter is not overloaded.

- For FGD performance control, the cold extractive NDIR-GFC analyzer MIR 9000 offers very high precision to measure online the SO2 or the SO2+O2.

CUSTOMER BENEFITS

- Important savings on reagent consumption and related costs

- Less reagent injected leads to a reduction of bottom ash quantity. Consequently, treatment costs of this solid outputs, most of time considered as hazardous, are significantly reduced.

- Improved process robustness, relibaility, optimisation and reduced maintenance costs

- Measuring the H2O content would avoid dampness of the reagent, which may lead to pasty deposits on the treatment filters.

- Reduction of stack emissions and therefore compliance with regulatory ELV limits and air pollution reduction

Stack emission control

| Thermal Power Plants (units) installed before December 31, 2003 | |

|---|---|

| Particulate Matter | 100 mg/Nm3 |

| Sulphur dioxide (SO2) | 600 mg/Nm3 (units smaller than 500 MW capacity) 200 mg/Nm3 (for units having capacity of 500 MW and above) |

| Nitrogen oxides (NOx) | 600 mg/Nm3 |

| Mercury (Hg) | 0.03 mg/Nm3 (for units having capacity of 500 MW and above) |

| Thermal Power Plants (units) after January 1, 2004, up to December 31, 2016 | |

| Particulate Matter | 50 mg/Nm3 |

| Sulphur dioxide (SO2) | 600 mg/Nm3 (units smaller than 500 MW capacity) 200 mg/Nm3 (for units having capacity of 500 MW and above) |

| Nitrogen oxides (NOx) | 300 mg/Nm3 |

| Mercury (Hg) | 0.03 mg/Nm3 |

| Thermal Power Plants (units) to be installed from January 1, 2017 | |

| Particulate Matter | 30 mg/Nm3 |

| Sulphur dioxide (SO2) | 100 mg/Nm3 |

| Nitrogen oxides (NOx) | 100 mg/Nm3 |

| Mercury (Hg) | 0.03 mg/Nm3 |

- For Gases SO2/NO/NO2/CO/CO2/O2 : the cold extractive multigas analyzer MIR 9000

- For Particulate matter: the QAL 182 WS for wet FGD plants and QAL 991 for dry FGD plants

- For Mercury: the SM-4

- And the ProPitotTM Approved Flue Gas Velocity CEM StackFlow 200 for stack velocity, volumetric flow, and pollutant mass release calculations

About ENVEA India (formerly known as Environnement SA India Pvt. Ltd):

With activities in India since the 1990’s, ENVEA India Pvt Ltd has delivered and installed hundreds of air pollution monitoring networks, perfectly addressing Indian Government supportive measures and regulations to curb air pollution. Furthermore, through its continuous stack emissions monitoring being installed in a huge number of industries across the territory such as: chemical & petrochemical industries, cement plants, metal & paper mills, etc., ENVEA assists their effort to come closer to compliance and meet pollution reduction goals. The subsidiary counts today over 250 employees, India being today the group’s third largest market.

ENVEA India Pv Ltd

D/ 16 3 & 4, TTC Industrial Area,

M.I.D.C., Turbhe, Navi Mumbai

400 705 – INDIA

+91 22 4502 0000

info.in@envea.global