Pharma

RELATED CASE STUDIES

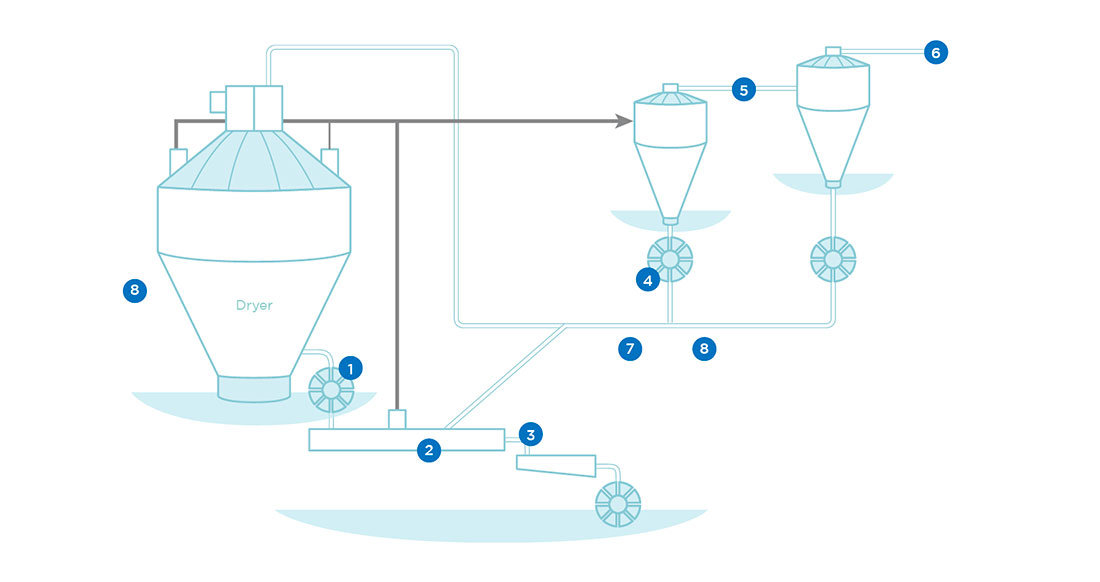

Improved fluidized bed drying process and energy saving thanks to continuous moisture measurement

-

-

Case study< BackPharmaceuticals manufacturer...

Continuous dust monitoring in ambient air at ceramic tile production site

-

-

Case study< BackCeramic tile manufacturer |...

HEPA filter emission monitoring for pharmaceutical powder processing

-

-

Case study< BackPharmaceutical Industry |...

Abatement of solvent emissions and odors: online VOC measurements

-

-

Case study< BackIndustries concerned:...