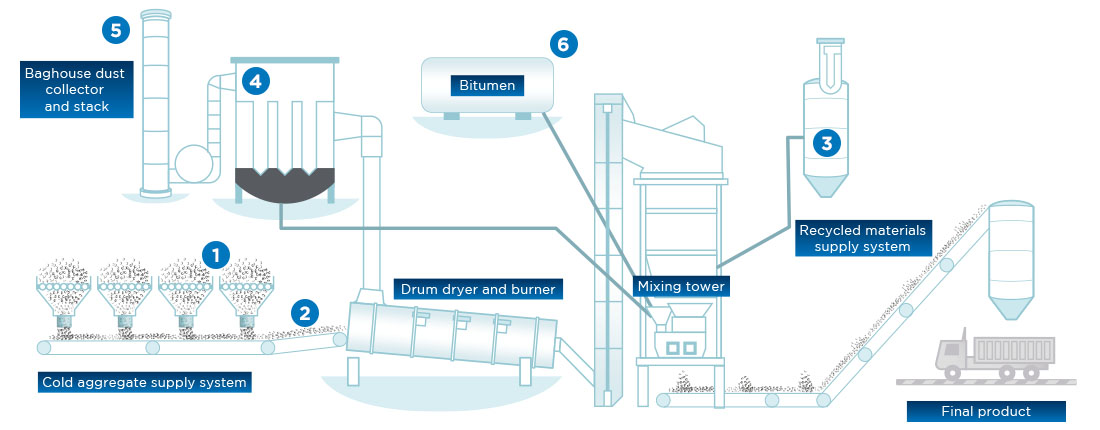

Asphalt

- on aggregates of all sizes, such as sand, that are sent to the rotary kiln via cold conveyors

- on recycled materials inserted in the mixing tower.

- on bitumen injected in the mixing tower. Requirement: it needs to be dry and cold.

- Optimized dryer combustion, reduced gas consumption

- Time saving and product quality improvement thanks to online and continuous moisture measurement

- Quick detection of production stoppages

- Reduced downtime and maintenance

- Online warning of materials level

- Quick detection of production jams

- Reduced downtime

- Increased productivity

- Reduced filter replacement costs

- Compliance with Emission Limit Values (ELV)

- Reduced environmental impact

- Help to reduce environmental impact on population

- Anticipate at-risk situations

- Reduce maintenance costs

Energy and costs savings, emissions monitoring

RELATED CASE STUDIES

Continuous dust monitoring in ambient air at ceramic tile production site

-

-

Case study< BackCeramic tile manufacturer |...

Asphalt production: EUROVIA chooses ENVEA for dust emissions monitoring

-

-

Case study< BackAsphalt production | PCME...

Abatement of solvent emissions and odors: online VOC measurements

-

-

Case study< BackIndustries concerned:...