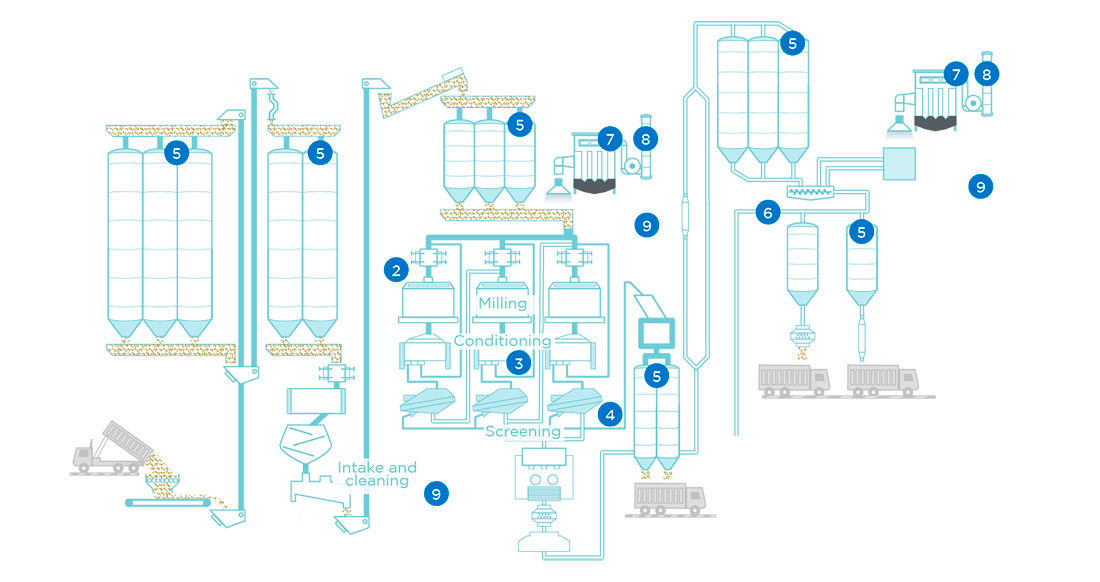

Agriculture

RELATED CASE STUDIES

Reduction in maintenance costs and process stability thanks to reliable raw cement mass flow measurement

-

-

Case study< BackConstruction materials...

Saving energy and resources – optimising the corn washing process through precise mass flow measurement

-

-

Case study< BackFood producer | MaxxFlow...

Continuous dust monitoring in ambient air at ceramic tile production site

-

-

Case study< BackCeramic tile manufacturer |...

Contactless material flow detection on conveyor belts

-

-

Case study< BackAgriculture industry |...

Online moisture measurement for solids – Application overview

-

-

Case study< BackApplication overview |...

Cereals moisture measurement for dryer efficiency

-

-

Case study< BackFood industry | M-Sens...