Metal

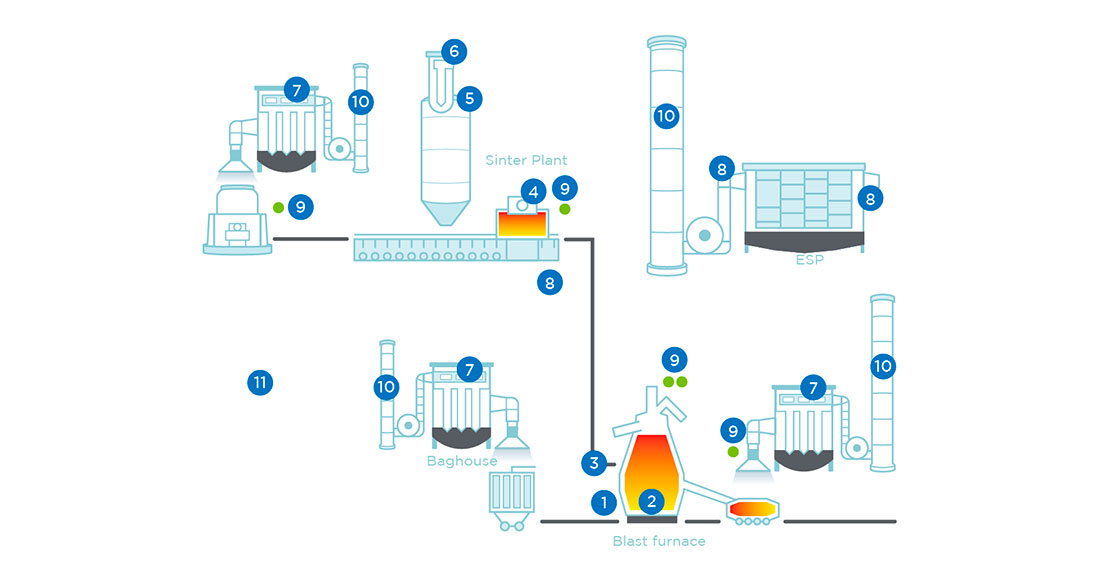

- Steel

- Galvanizing

- Foundry

- Aluminum recycling

- Aluminum smelting

- Nickel smelting

- Precious smelting

- Zinc recycling

- Zinc smelting

- Copper recycling

- Copper smelting

- Ferrous foundry

- Lead recycling

- Lead smelting

-

e-Series Nitrogen Oxides Analyzer NO, NOx & NO₂

AC32e dilution

-

e-Series Sulfur dioxides Analyzer SO₂

AF22e

-

Ambient air dust monitoring

AirSafe 2

-

Indoor Monitor for Dust Exposure for PM1, PM2.5, PM4.25, PM10, TSP

AirSafe PM

-

e-Series carbon oxides Analyzer CO

CO12e

-

Total Hydrocarbons FID Analyzer

HC51M

-

All-in-one Portable real-time Hg monitor

Mercury Tracker-3000 XS

-

Volatile Organic Compounds Analyzer BTEX

VOC72e

RELATED CASE STUDIES

Improved efficiency of blast furnace – Optimizing PCI applications with mass flow measurement

-

-

Case study< BackSteel Plant |...

Improving spray painting stations with powder flow monitoring

-

-

Case study< BackAutomotive industry| FlowJam...

Continuous dust monitoring in ambient air at ceramic tile production site

-

-

Case study< BackCeramic tile manufacturer |...

Steel industry: new CEMS monitoring project for ENVEA in Egypt

-

-

Case study< BackSteel industry | MIR 9000,...

Filter damage monitoring of metal grinding dust

-

-

Case study< BackOther| DustyCustomer: Coil...

Detection of metal dust in a clear gas site after bag filter

-

-

Case study< BackOther | ProSensCustomer:...