Mass flow measurement for dry bulk solids

Contact-less and maintenance free measurement of high mass flow rates of dry bulk solids independent of pipe run

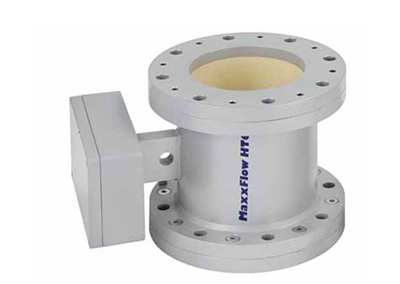

Electromagnetic flowmeter, designed to measure bulk material flows up to 300 t/h.

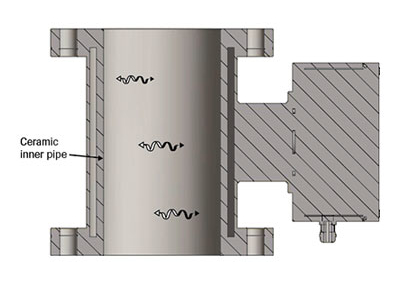

The meter has no mechanical parts in the flow, is 100 % dustproof and erosion free thanks to the ceramic inner pipe.

- arbitrary mounting position (inclined/free fall)

- low headroom required

- easy to calibrate

Flow measurement from 10 t/h to 300 t/h

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Most non-metallic solids can be measured

- Can be installed on round pipes or ducts

- No real upper limit of mass flow

- Maximum pressure 10 bar

- Dust tight

- No flow restrictions to the process flow (wear resistant ceramic liner)

- The mass flow measurement is independent of flow characteristics

- Maximum temperature, 12O °C

- Can be installed at an angle

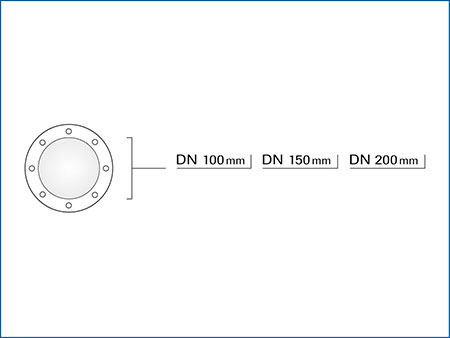

- Small footprint, 220 mm (DN 100), 290 mm (DN 150), 310 mm (DN 200)

- No moving parts, hence no maintenance

– Low installation height

– Suitable in situations in which it was previously only possible to use complicated, inaccurate or expensive mechanical solutions (impact plates, measuring chutes)

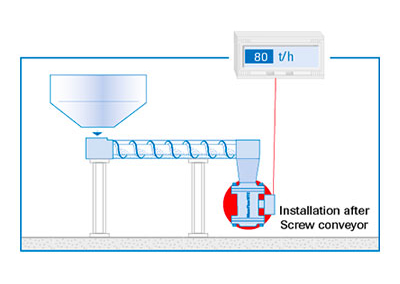

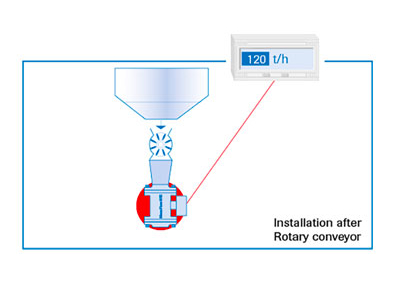

Installation independently of direction of line (vertical, inclined), but always after mechanical conveyor elements, in various industries:

- Cement

- Chemistry

- Energy

- Coal plant

- Food

- Minerals

- Lime plant

- Gypsum

- Mass-flow measurement of raw meal

- Mass-flow measurement of potato starch in free fall prefiding chain conveyors

- Mass-flow measurement of salt in free fall pre feeding chain conveyor

- Mass-flow measurement of wood pellets in free fall

- Flow mettering of grains

| Technical Specifications | |

|---|---|

| Material to measure | Dust, powders or granulates max grain size 30 mm |

| Working principle | Electromagnetic |

| Process pressure | 1 bar |

| Process temperature | Up to +120°C |

| Mounting | Flange build-in |

| Type of Conveying | Gravity, also declining pipes |

| Flow rates | Up to 300 t/h |

| Pipe diameter | Up to 200 mm feeder outlet |

| Output | 4…20mA, Modbus, Profibus |

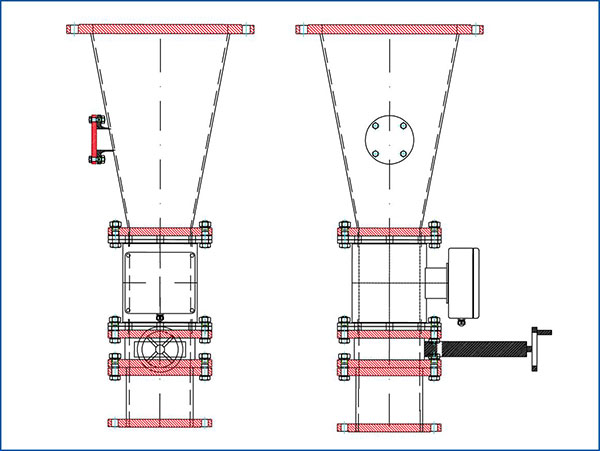

The MaxxFlow HTC is specially developed for the flow measurement of dry bulk solids during high-volume throughput. Due to its completely open profile and its low installation height, the MaxxFlow HTC is especially suitable in situation in which it was previously only possible to use complicated or expensive mechanical solutions, e. g. impact plates or measuring chutes.

The installation of the MaxxFlow HTC takes place independently of the direction of the line (vertical/inclined), but always after mechanical conveyor elements,

e. g. rotary feeder, screw conveyors, air slides or chain conveyors.

| Sensor Technical Data | |

|---|---|

| Housing | Steel St 52, powder-coated (optional stainless steel 1.4571) NW 80/100/150/200 mm, Flange according EN 1092-1 / PN10 DN 80: variable |

| Inner Type | Al2 O3-Ceramic |

| Operating temperature | Sensor pipe: – 20 … + 120 °C Sensor electronic: 0 … + 60 °C |

| Max. working pressure | 1 bar |

| Working frequency | 88 kHz |

| Transmitting power | Max. 2 mW |

| Weight | Depend on diameter |

| Accuracy | ± 1 … 3 % (based on end of measuring range and calibrated material) |

| System accuracy | ± 0.04 % |

| Transmitter Technical Data | ||||

|---|---|---|---|---|

| MSE 300-DR (DIN Rail) | MSE 300-FH (field housing) | |||

| Power supply | 24 V DC ±10 % | 110 / 230 V AC 50 Hz (optional 24 V DC) |

||

| Power consumption | 20 W / 24 VA | |||

| Protection type | IP 40 to EN 60 529 | IP 65 to EN 60 529/10.91 | ||

| Ambient operating temperature | -10 … +45 °C | |||

| Dimensions (W x H x D) | 23 x 90 x 118 mm | 258 x 237 x 174 mm | ||

| Weight | Approx. 172 g | Approx. 2.5 kg | ||

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14] | |||

| Current output | 1 x 4 … 20 mA (0 … 20 mA), load < 500 Ω (Active) |

3 x 4 … 20 mA (0 … 20 mA), load < 500 Ω (Active) |

||

| Interface | RS 485 (ModBus RTU) / USB | |||

| Pulse output | Open collector – max. 30 V, 20 mA | |||

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA) |

|||

| Data backup | Flash memory | |||

| DIN rail fastening DIN 60715 TH35 |

Cable screw connectors 3 x M20 (4,5 – 13 mm Ø) |

|||

| A complete measuring station consists of these components:

• Measuring feeder for installation in the conveyor line The measuring feeder is available in sizes DN 100, DN 150 mm and DN 200 mm. The transmitter is connected to the sensor using 4-wired, shielded cable. |

|