- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Absolutely insensitive to material caking

- Can be used up to a profile of 25 m (larger profiles on request)

- Can be used with adapter up to 220 °C and 20 bar

- With ceramic mounting, usable up to 1,000 °C

- Signalling through relay switching

- Detection through non-conductive walls

- Extra short sensor with separate analysis unit

- No measurement failure because of strong material flow for filling

- Limestone

- Tiling

- Waste incineration

- Cement

- Building materials

| Technical Specifications | |

|---|---|

| Material to measure | Dust, powders or granulates |

| Working principle | Microwave |

| Silo diameter/ detection range | 25m |

| Process pressure | Max. 20 bar |

| Process temperature | Up to 1000°C |

| Mounting | 1 1/2 ” threat connection |

| Place to measure | Silos, containers, chutes, pipelines, transition points |

| ATEX rating | Category 3 |

| Output | Relay |

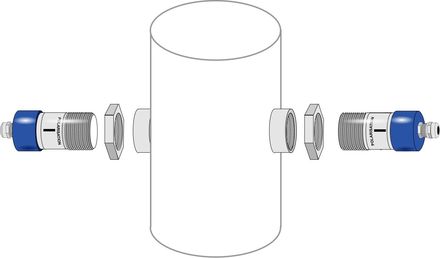

- The microwave barrier is a contactless measuring procedure

- Can be installed in containers, pipelines, shafts or free-fall sections

- Range is 0.1 … 25 m

- If container walls, housings or pipelines are not metal, it is possible to measure from the outside

- Can also be used under difficult conditions such as high operating temperatures and pressures with the help of a process-adapter

- The use of microwaves also ensures a high level of insensitivity to any caking on the sensor window

| Technical Data | |

|---|---|

| Material | Housing: Stainless steel 1.4571 Sensor-Isolation: POM |

| Protective system | IP 65 |

| Process temperature | -20…+80 °C -20…+220 °C (with process adapter) Max. 1000 °C (with ceramic flange) |

| Ambient temperature | -20…+60 °C |

| Working pressure | Max. 1 bar Max. 20 bar (with process adapter) |

| Detection range | 0.1 … 25 m |

| Power supply | M24 V DC (- 10 / +15 %) 24 V AC (- 10 / +15 %) |

| Power consumption | Max. 20 VA |

| Current consumption | Max. 850 mA |

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V/5 mA) |

| Response time | 0.25 …5 s (continuously adjustable) |

| Measuring frequency | K-Band 24.125 GHz (± 100 MHz) |

| Transmitting power | Max. 5 mW |

| Weight | Transmitter: 1.1 kg Receiver: 1.1 kg |

| Technical Data | ||||

|---|---|---|---|---|

| Pressure adapter | Temperature adapter | Food adapter | High temperature adapter | |

| Material | Stainless steel 1.4571, POM diaphragm |

Stainless steel 1.4571, Tecapeek diaphragm |

Stainless steel 1.4571, Tecapeek GF30 diaphragm |

Steel Ceramic diaphragm |

| Temperature | -20…+80 °C | Max. +220 °C | Max. +220 °C | Max. 1000 °C |

| Pressure | Max. 20 bar | Max. 20 bar | Max. 20 bar | Max. 40 bar |

| Thread | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on sensor sides |

| Wrench width | 55 mm | 55 mm | 55 mm | 17 mm |

The ProGap S can be easily installed in the following ways:

The fitting position of the devices is arbitrary. Important is that transmitter and receiver are positioned precisely to each other. The adjustment is made by means of a counter-screw fitting. Commissioning will be done by evaluation unit. |

|