APPLICATION

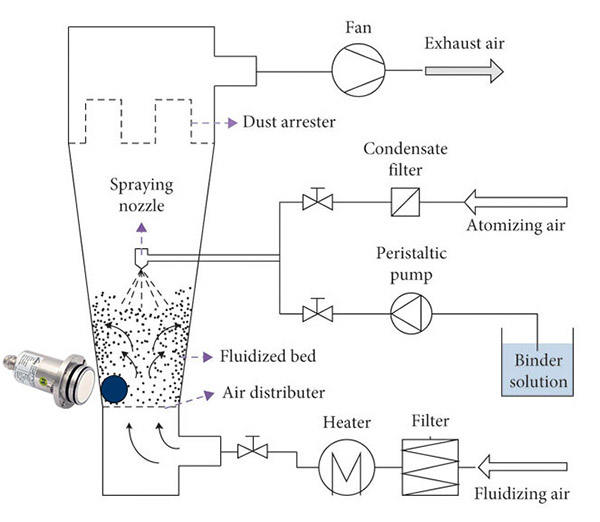

The fluidized bed one-step granulation process is a technology that dries and granulates powdered materials through a gaseous fluidized bed. It guarantees energy & material saving along with continuous production compared to the traditional split-drying and granulation process.

In the fluidized bed one-step granulation process, moisture measurement has an important role. It helps to adjust the heating temperature, air flow and other parameters according to the real-time measuring data and to make the granulation process more stable and controllable. Moisture measurement also enables to control the size and uniformity of the granules. A large amount of moisture will lead to oversized and caked granules, while a small amount of moisture will lead to small and fragile granules, affecting the quality of the product.

Moisture is an important indicator of the control and quality of fluidized bed one-step granulation, so customer looked for a way to measure moisture in the process.

SOLUTION

In the described application, the sensor was mounted at the bottom of the fluidized bed, ensuring that the sensor measuring surface could be completely covered by the material.

In practice, the sensor measuring surface was flush with the inner wall of the fluidized bed.

Finally, M-Sens is compact and easy to install, it doesn’t require any mechanical sampling device, thus guaranteeing time and cost savings.

CUSTOMER BENEFITS

- Optimized drying processes and reduced energy consumption

- Improved product quality and consistency thanks to continuous moisture measurement

- Simple and fast sensor calibration