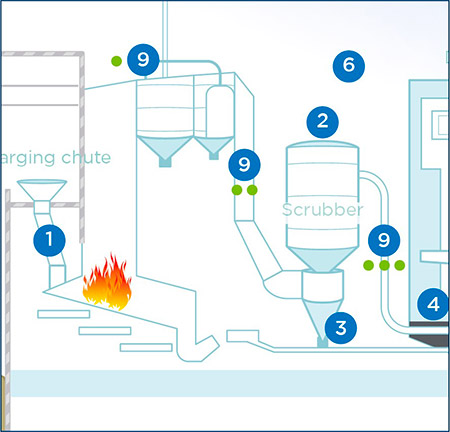

FGD, DeNOx, DeSOx – control precisely the absorber/neutralizer injection

Material: raw gases HCl, NOx, Hg, SO2, (CO, O2, H2O)

Installation: before the injection point

Function: online monitoring of gas parameters allowing for precise adjustment of absorber/neutralizer injection, to comply with emission regulations (ELV)

(9) •• Polluants abatement

During combustion or incineration process, acids are produced due to the composition of the fuels or plastics or other materials contained in the waste. Neutralization/absorption of these species prior to the dust filtration treatment is essential to avoid damage to the filter media and excess of emissions.

This operation is carried out by injecting a quantity of lime, limestone slurry, active carbon powder or sodium bicarbonate powder proportional to the pollutant concentrations (dioxins, furans, heavy metals, acids).

In order to adjust precisely this pollutant reduction in real time, on-line monitoring of HCl, NOx, Hg or SO2 (precursor of SO3 and sulfuric acid derivates) must be set on the process, before the injection point.

Measuring the water content could also be interesting as it would allow the detection of a possible leak in the boiler.

This operation is carried out by injecting a quantity of lime, limestone slurry, active carbon powder or sodium bicarbonate powder proportional to the pollutant concentrations (dioxins, furans, heavy metals, acids).

In order to adjust precisely this pollutant reduction in real time, on-line monitoring of HCl, NOx, Hg or SO2 (precursor of SO3 and sulfuric acid derivates) must be set on the process, before the injection point.

Measuring the water content could also be interesting as it would allow the detection of a possible leak in the boiler.

Solution

CUSTOMER BENEFITS

- Important savings on reagent consumption and related costs.

- Less reagent injected lead to a reduction of bottom ash quantity. Consequently, treatment costs of this solid outputs, most of time considered as hazardous, are significantly reduced.

- Improved process robustness and reduced maintenance.

- Reduction of stack emissions and therefore compliance with regulatory ELV limits and air pollution reduction.

- Measuring the H2O content would avoid dampness of the reagent, which may lead to pasty deposits on the treatment filters, as well as the detection of a possible leak in the boiler.

Related content

Download the case study

Information request