Technology for dust concentration measurement after Electrostatic Precipitators or in large stacks

DynamicOpacity™ Ratiometric Opacity technology provides a rugged solution to dust concentration measurement for the dust loadings found after Electrostatic Precipitators or in large stacks in Power, Steel, Cement Plant.

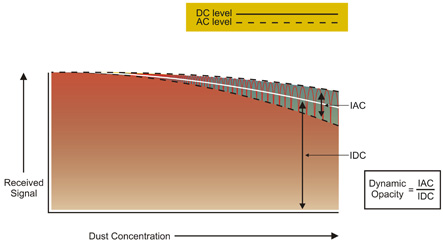

Its ratiometric measurement algorithm provides automatic self-compensating contamination elimination and therefore a rugged alternative to opacity monitoring in industrial applications regulated in terms of mg/m3 instead of historical opacity (colour).

- Core Features of the Technology are:

- Ratiometric measurement permits accurate measurement when lens contaminated up to 90%.

- Instrument can measure in both DynamicOpacity™ and opacity mode and provide concentration and opacity outputs

- Compared to Opacity systems, DynamicOpacity™ systems are far less susceptible to errors caused by lens contamination. In practice, this means they need far less instrument maintenance and smaller air purging systems.

- Due to its ratiometric algorithm, DynamicOpacity™ is much less subject to misalignment.

- Compared to other ratiometric opacity systems, the instruments use an optimised frequency bandwidth which improves the quality of the dust measurement to be accurate enough to pass TUV and MCERTS approvals.

- Automatic electronic Opacity zero and span checks performed by varying the light intensity in the transmitter head.

- Automatic electronic DynamicOpacity™ zero and span checks, to test scintillation count at zero and full scale.

- Optional hand held external Electronic Audit Unit for zero and linearity checks

- Comms check, to test control unit correctly communicating with and reading dynamic opacity readings from the sensor(s).