APPLICATION

ENVEA was consulted by the customer in order to provide a continuous monitoring solution for CO, NOx, O2 and VOC parameters that could meet what is required in the European standard EN16510-1:2019 in order to guarantee compliance of the products they manufacture.

The standard specifies the requirements for the design, manufacture, construction, safety and performance (efficiency and emissions) of solid fuel-fired appliances and provides related instructions also covering the test methods of CO, NOx, VOC and particulate emissions.

It mandatorily requires the use of NDIR technology for CO, NOx and O2 measurement (chemiluminescence is also accepted for NOx measurement) and FID technology for VOC measurement.

Solution

- Sampling system complete with a line to transport the sample gas

- MIR9000e multi-parameter analyzer with NDIR technology for the measurement of CO, NOx and O2, which, thanks to its high level metrological performance, reliability, and man-machine interface, turns out to be the suitable product both for the measurement of components during regular and occasional emissions

- Graphite 52 analyzer with FID technology for the measurement of VOC, already used by certified industry laboratories, which thanks to its performance and reliability turns out to be the suitable product both for the measurement of components during regular and occasional emissions

- PT100 temperature sensor

- Data acquisition and validation system fully customized according to application needs

- Analysis rack equipped with wheels for easy handling

The analysis rack was placed inside the test room near the chimney connected to the equipment (stoves, etc…) under test.

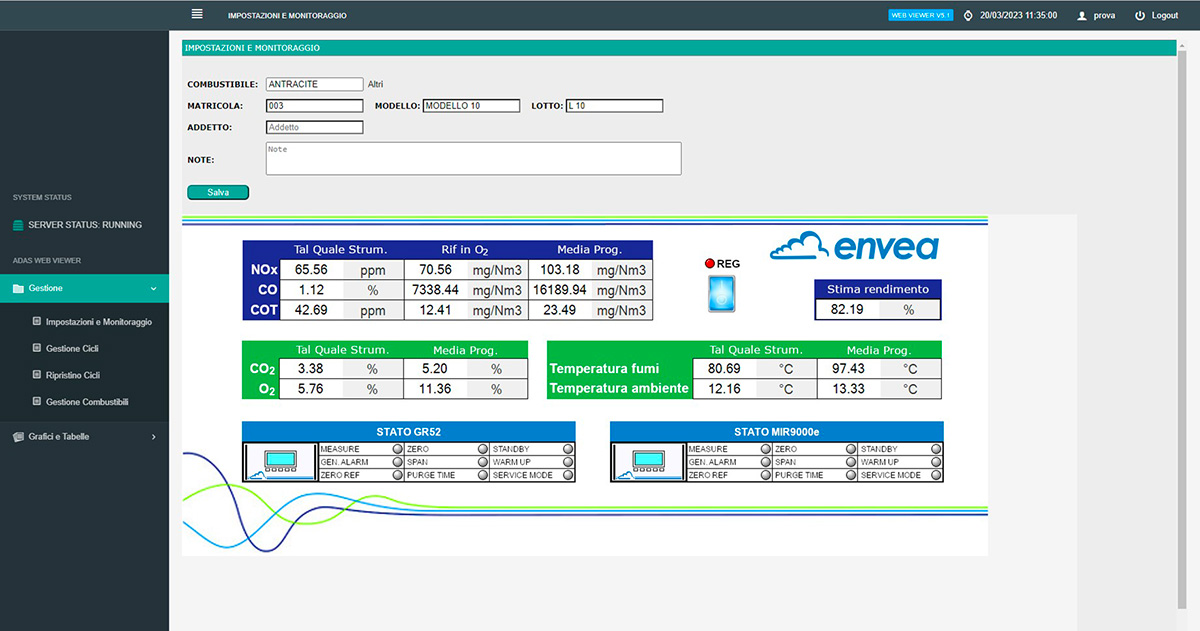

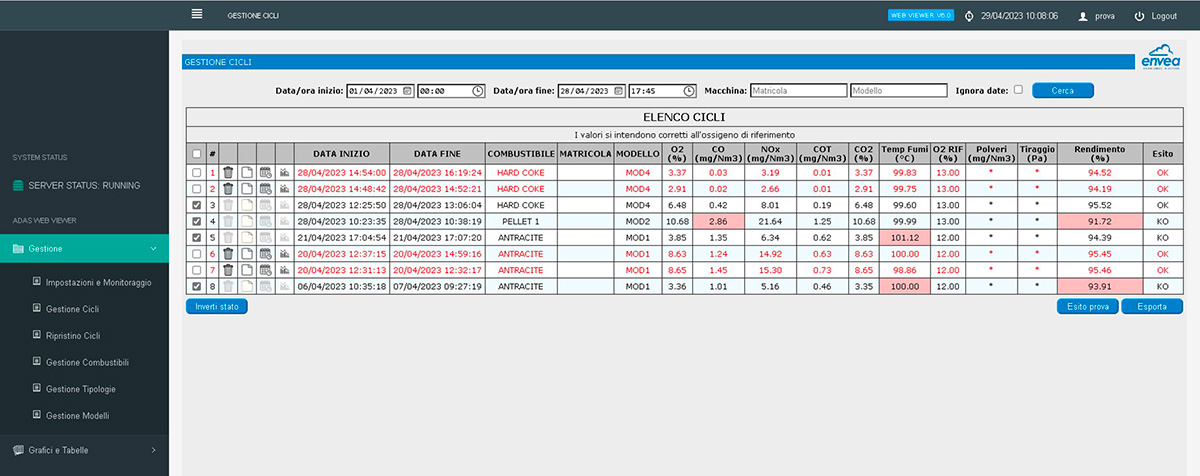

The solution was integrated with customized software developed at the customer’s request with the following features:

- WEB based software interface (can be accessed through a common browser from any PC, tablet, smartphone connected to the system)

- Data acquisition and storage at the rate of one sample per second

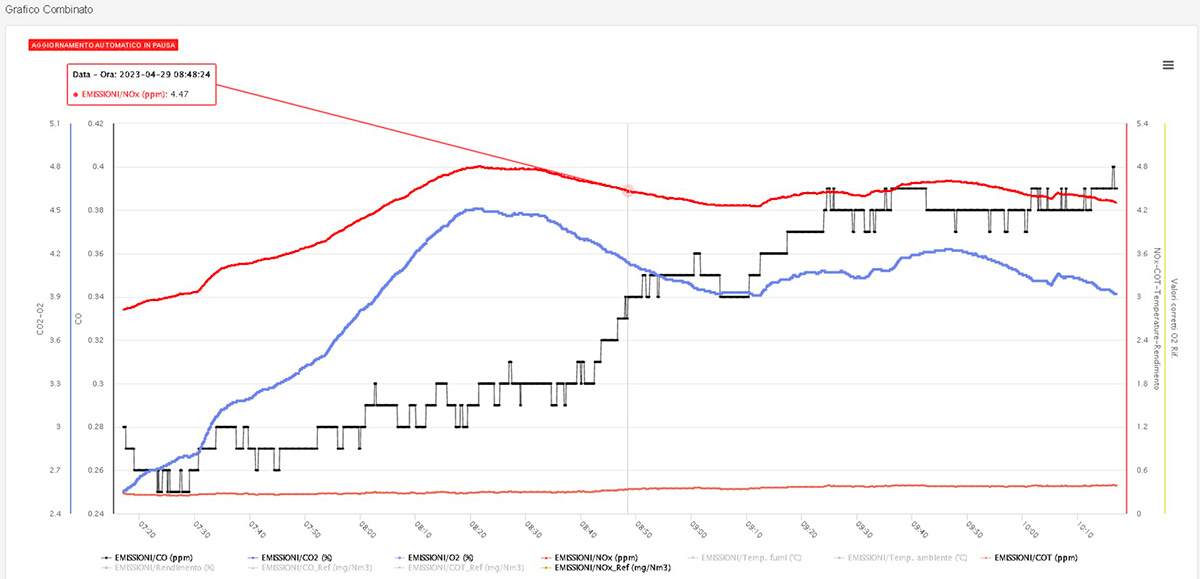

- Real-time data visualization

- Automatic cycle identification

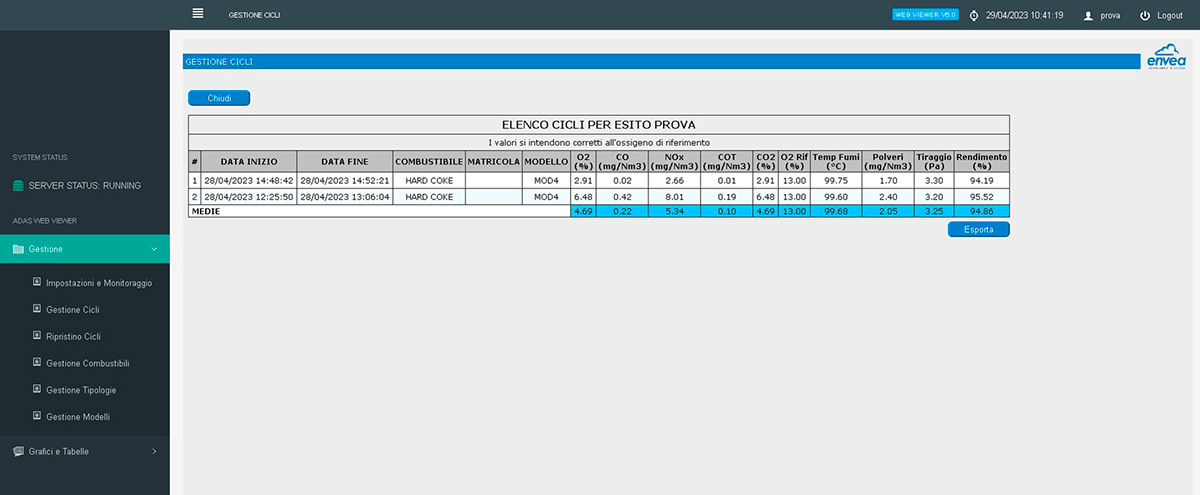

- Advanced cycle management

- Fuel master data management

- Calculation of emissions and efficiency on single cycle and on tests of multiple cycles in accordance with EN 16510

- Export of acquired data and results to Excel

- Implementation of numerical communication protocols for interfacing with enterprise management systems (Industry 4.0)

CUSTOMER BENEFITS

- EN16510-1:2019 compliant solution

- Optimized efficiency of the heating system and its emissions thanks to a precise and reliable analysis of pollutants

- Solution prepared for Industry 4.0

- Fully customizable solution