Gas Analyzers

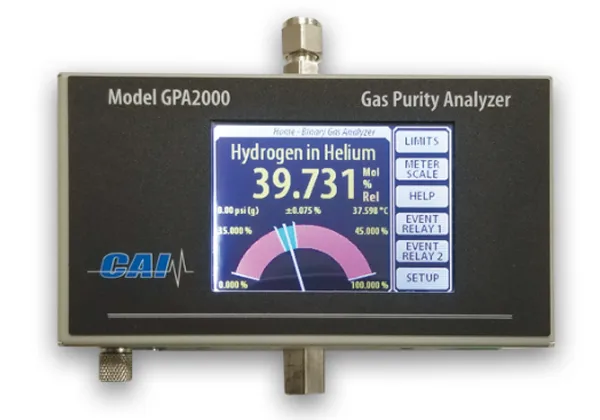

Gas Purity (GPA) Analyzers

GPA 2000 Series Gas Purity Analyzers utilize the speed of sound to accurately detect the concentration of one gas in the presence of another.

GPA 2000 software allows the end user to reconfigure the unit for a wide variety of different gas combinations, making it an ideal choice for gas cylinder filling operations. The GPA 2000 can applied in a variety of different applications:

- Verifying gas cylinder-filling operations for welding, diving, medical, laser and analyzer calibration gas mixtures.

- Verifying specialty gas blends used in the semiconductor industry (e.g. Formic Acid in N2).

- H2 purity analysis for turbine generators used in power plants.

- Verifying the N2 purity from nitrogen skid generators.

- Heat treating / annealing furnace applications (e.g. 10% H2 in N2).

- Gas purity analysis of H2 and O2 gases generated by large-scale electrolysis plants.

- Analysis of H2 purity from pressure swing absorption (PSA) units.

CAI Speed-of-Sound Gas Purity Analyzer Highlights

- Maintenance-free resonant acoustic sample cell (304SS).

- No need for field recalibration after factory-characterization of the RASC.

- No need for reference or calibration gases, no consumables, no GC columns, etc.

- Software allows the end user to select from a menu of over 500 different gases.

- Software allows the end user to remotely change the binary gas mixture of interest (e.g. from CO2 in N2 to H2 in He) with no need of recalibration.

- Software allows the end user to remotely start and stop the analysis, chart the analyzer’s output which can then be printed and used to support gas cylinder certification requirements.