Détection de fuites / Filtre à particules ElectroDynamic®

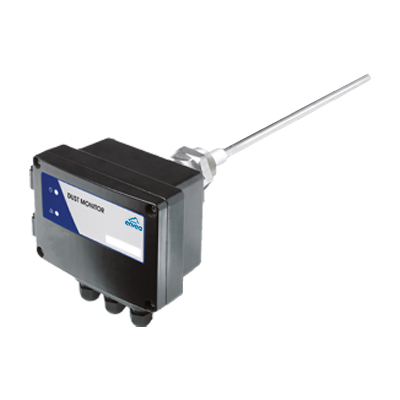

Utilisant la technologie brevetée ElectroDynamicTM, le DUST MONITOR 210 est un détecteur de fuite de poussières adapté aux applications de contrôle des filtres après dépoussiéreur à manches filtrantes (filtre à manche).

L’instrument permet une surveillance robuste et fiable des fuites de poussières. Des options sont disponibles pour une utilisation en zone explosive UKEX/ ATEX /IECEx ou pour une installation en mode mono-capteur autonome avec son boitier de commande.

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Approvals & Certifications

- Downloads

- High-quality leak response with sufficient dynamic range and time response to track emissions from single and multi-compartment pulse cleaned bag filters

- System self-checks (drift checks) to validate measurement integrity including automatic Zero and Span checking

- Insulated sensor rod option for unmatched performance in applications where water condensation is likely

- Integrated user interface with keypad and display for intuitive instrument set-up and use

- 0-100% or user scalable display, of assistance to plant operators wishing to manually scale the display to an approximate known dust level

- Quarrying eg Rotary Dryers, Roller Mills

- HEPA filters e.g. pharmaceutical/biomedical plant

- Coal Mill / Cement Mill/ Cement Kiln arrestment plant

- Humid applications eg Dryers, Calcinators

- Wood cutting & chipping plant

| Technical Specifications | |

|---|---|

| Measured parameters | Dust |

| Technology | Electrodynamic™ Probe Electrification |

| Measurement/Monitoring capability | 0-500 mg/m3 (Leak monitoring) |

| Stack/Duct diameter suitability | 0.5 to 8 m |

| Flue gas temperature | 250°C standard, 400°C option |

| Baghouse | YES |

| Cartridge Filter | YES |

| Ceramic Filter | YES |

| Coalescent Filter | YES |

| Cyclone | YES |

| Electrostatic Precipitator (ESP) | NO |

| Wet Electrostatic Precipitator (WESP) | NO |

| Wet Scrubber | NO |

| Sensor variants | 316 stainless, or fully insulted PTFE coated option for conductive dust or humid flue gas application (Sensor Probe) |

| QA checks | YES if required by the user or regulator. |

| Technical data | |

|---|---|

| Measurement capability | 0-500 mg/m3 (Leak monitoring) |

| Sensor Variants | 316 stainless, or fully insulted PTFE coated option for conductive dust or humid flue gas application (Sensor Probe) |

| Stack Temperature Ranges | 250°C up to 400°C option |

| Functionality and QA Checks | Automatic zero and span |

| Data Output | RS485 (Modbus) output to Controller |

| Air Purge | option |

| Enclosure Protection Rating | IP65 die-cast aluminium Enclosure |

- UKEX/ ATEX / IECEx Dust Zones 20, 21, 22

- US EPA MACT Compliant