Solids mass flow measurement up to 20 t/h

Continuous mass flow measurement of all types of dust, powder and granules in free fall and pneumatic conveying

Microwave sensor for on-line mass flow measurement of solids up to 20 t/h.

Used in pneumatic leanphase conveying or vertical freefall after mechanical feeders.

- easy installation via weld-on socket

- for almost all types of dusts, powders, granules

- uses field-proven technology with active roping compensation

- suitable for nearly all pipe diameters

Measurement for flow rates up to 20 t/h

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Simple retrofitting using a welding socket

- ATEX-certified

- Almost all types of dust, powder and granules can be measured

- No installations in the material stream

- Measuring principle: Microwave

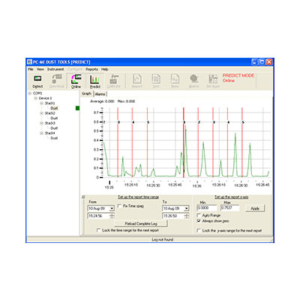

- Online flow metering

- Throughput measuring flowrates up to 20 t/h

- Active roping compensation for highest reliability

- Wear-resistant

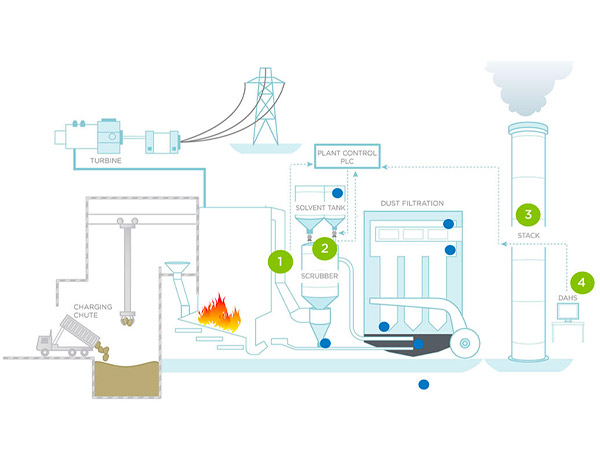

- Biomass

- Cement

- Chemistry

- Coal plant

- Coating

- Food

- Incineration

- Minerals

- Wood

- Lime plant

- Energy

- Gypsum

- Power plant

- Foundry

| Technical Specifications | |

|---|---|

| Material to measure | Dust, powders or granulates max. grain size 20 mm |

| Working principle | Microwave |

| Process pressure | 1 bar, optional 10 bar |

| Process temperature | +200°C, optional up to +900°C |

| Mounting | Via process connection |

| Type of Conveying | Pneumatic leanphase, vertical freefall after feeder |

| Flow rates | Up to 20 t/h |

| Pipe diameter | Max. 800mm |

| ATEX rating | Category 1/2 |

| Output | 4…20mA, Modbus, Profibus |

SolidFlow 2.0 is a sensor especially developed for measuring the flow rate of solids conveyed in metallic ducts.

It has successfully been tested for online-measuring of:

- all types of dust, powder and granulates

- grain size between 1 nm and 1 cm

- pneumatically conveyed materials or

- in free fall after mechanical conveying systems

- SolidFlow is wear-resistant and the commissioning is very easy.

| Sensor Technical Data | |

|---|---|

| Housing | Stainless steel 1.4571 |

| Protection category | IP 65, DustEx zone 20 or GasEx zone 1 (optional) |

| Operating temperature | Front end of sensor: -20… +80 °C Optional: -20 … +200 °C Sensor electronic: 0 … +60 °C |

| Max. working pressure | 1 bar, optional 10 bar |

| Working frequency | K-Band 24.125 GHz, ±100 MHz |

| Transmitting power | Max. 5 mW |

| Weight | 1.3 kg |

| Dimensions | Ø 60, Ø 20, L 271 mm |

| Accuracy | ± 2 … 5 % in calibrated range |

| Transmitter Technical Data | ||||

|---|---|---|---|---|

| Transmitter (DIN Rail) | Transmitter (field housing) | |||

| Power supply | 24 V DC ±10 % | 110 / 230 V AC 50 Hz (optional 24 V DC) |

||

| Power consumption | 20 W / 24 VA | |||

| Protection type | IP 40 to EN 60 529 | IP 65 to EN 60 529/10.91 | ||

| Ambient operating temperature | -10 … +45 °C | |||

| Dimensions (W x H x D) | 23 x 90 x 118 mm | 258 x 237 x 174 mm | ||

| Weight | Approx. 172 g | Approx. 2.5 kg | ||

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14] | |||

| Current output | 1 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

3 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

||

| Interface | RS 485 (ModBus RTU) / USB | |||

| Pulse output | Open collector – max. 30 V, 20 mA | |||

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA) |

|||

| Data backup | Flash memory | |||

| DIN rail fastening DIN 60715 TH35 |

Cable screw connectors 3 x M20 (4,5 – 13 mm Ø) |

|||

|

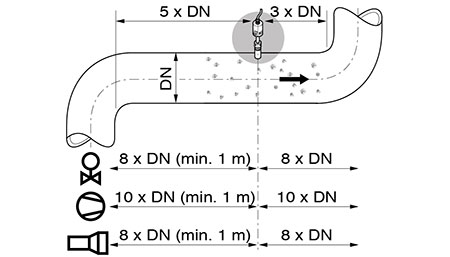

For the assembly of the sensor, the installation location is specified in accordance with the conveyed inlet and outlet paths. Commissioning: |

|