Mesure du débit massique de matières solides

Mesure du débit massique de matières solides en continu lors du transport pneumatique en phase dense à haut débit

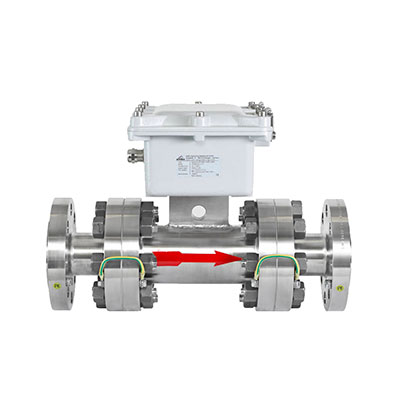

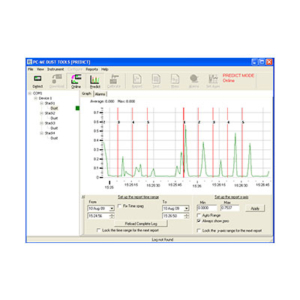

Le DensFlow est un système conçu pour mesurer le débit de matières solides lors du transport pneumatique en phase dense. Le capteur mesure la densité et la vitesse de la matière.

Version haute pression disponible, jusqu’à 110 bar.

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Reliable flow metering in pneumatic dense-stream

- Unlimited throughput volumes can be measured

- Optionally pressure-resistant up to 25 bar

- Installation creates no obstacle in the profile, hence no dead spots in which residue can form

- Measurement independent of the flow speed of the material

- Simple retrofitting

- Maintenance-free

- Contactless measuring procedure (no mechanics)

- Materials: Powder or granules in pneumatic dense-stream transport in steel industry

| Technical Specifications | |

|---|---|

| Material to measure | Dust and powders |

| Working principle | Electromagnetic |

| Process pressure | 25 bar, optional up to 110 bar |

| Process temperature | Up to +120°C |

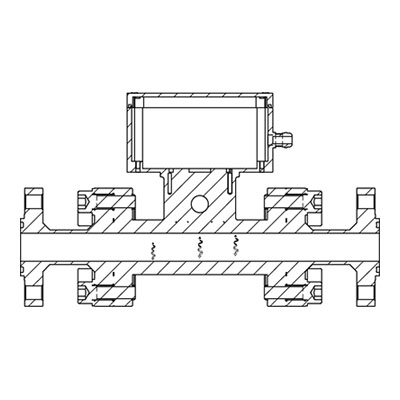

| Mounting | Flange build-in |

| Type of Conveying | Pneumatic densphase |

| Flow rates | No limit |

| Pipe diameter | Max. DN 150mm |

| ATEX rating | Category 3, Cat. 1 applied |

| Output | 4…20mA, Modbus, Profibus |

| Sensor Technical Data | |

|---|---|

| Housing | Steel St 52, powder-coated (optional Stainless steel 1.4571 DN 10…125 mm (bigger diameters on demand) Flange EN 1092-1 |

| Inner pipe | Ceramic |

| Protection category | IP65 |

| Ambient temperature Mediums temperature |

Sensor electronic: 0 … +60 °C Sensor pipe: 0 …+80 °C (higher temperatures as option) |

| Working pressure | Max. 25 bar, optional 64 bar |

| Working frequency | 88 kHz |

| Weight | Depending on the nominal diameter |

| Velocity range | 1…10 m/s |

| Dimension | Ø DN + 150 mm, L 500 mm |

| Accuracy | ± 2…5 % in calibrated range |

| Transmitter Technical Data | ||||

|---|---|---|---|---|

| Transmitter (DIN Rail) | Transmitter (field housing) | |||

| Power supply | 24 V DC ±10 % | 110 / 230 V AC 50 Hz (optional 24 V DC) |

||

| Power consumption | 20 W / 24 VA | |||

| Protection type | IP 40 to EN 60 529 | IP 65 to EN 60 529/10.91 | ||

| Ambient operating temperature | -10 … +45 °C | |||

| Dimensions (W x H x D) | 23 x 90 x 118 mm | 258 x 237 x 174 mm | ||

| Weight | Approx. 172 g | Approx. 2.5 kg | ||

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14] | |||

| Current output | 1 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

3 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

||

| Interface | RS 485 (ModBus RTU) / USB | |||

| Pulse output | Open collector – max. 30 V, 20 mA | |||

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA) |

|||

| Data backup | Flash memory | |||

| In pneumatic dense-stream conveying , the installation point is specified in accordance with the conveyed inlet and outlet paths.

The assembly of the measuring tube at the specified installation point takes place using a flange installation. Measuring tubes can be supplied in standard form in nominal widths of up to 150 mm with flange connections in accordance with DIN 2576. |

|