APPLICATION

The quantity of limestone was determined on the basis of the theoretical data provided by the plant operator’s employees, however, the objective was to measure the material flow rate continuously.

SOLUTION

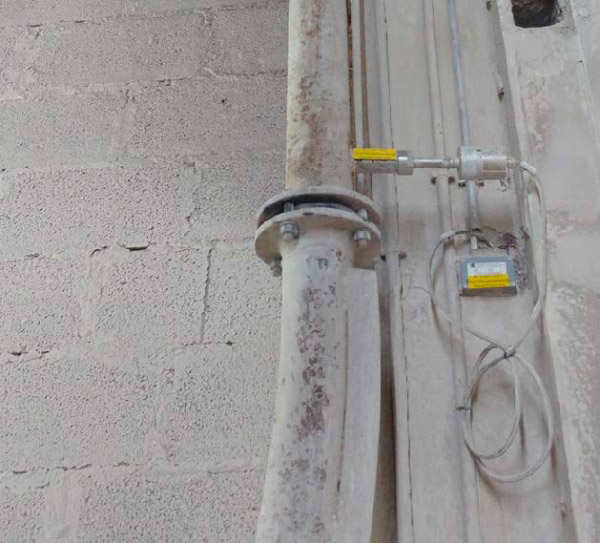

This allows measurement errors that occur due to roping to be compensated. In the described application SolidFlow 2.0 is used in the pneumatic transport line.

The sensor can be calibrated and transmits the exact measurement data to the control system. Ease of installation together with simple calibration features, the SolidFlow 2.0 is proven as an extremely effective mass flow measurement system for bulk solids.

CUSTOMER BENEFITS

- robust, durable, process-safe sensor technology

- simple, fast calibration

- detailed verification of the flow rates

- non-intrusive installation